IMMERSION SAMPLERS

IMMERSION SAMPLERS

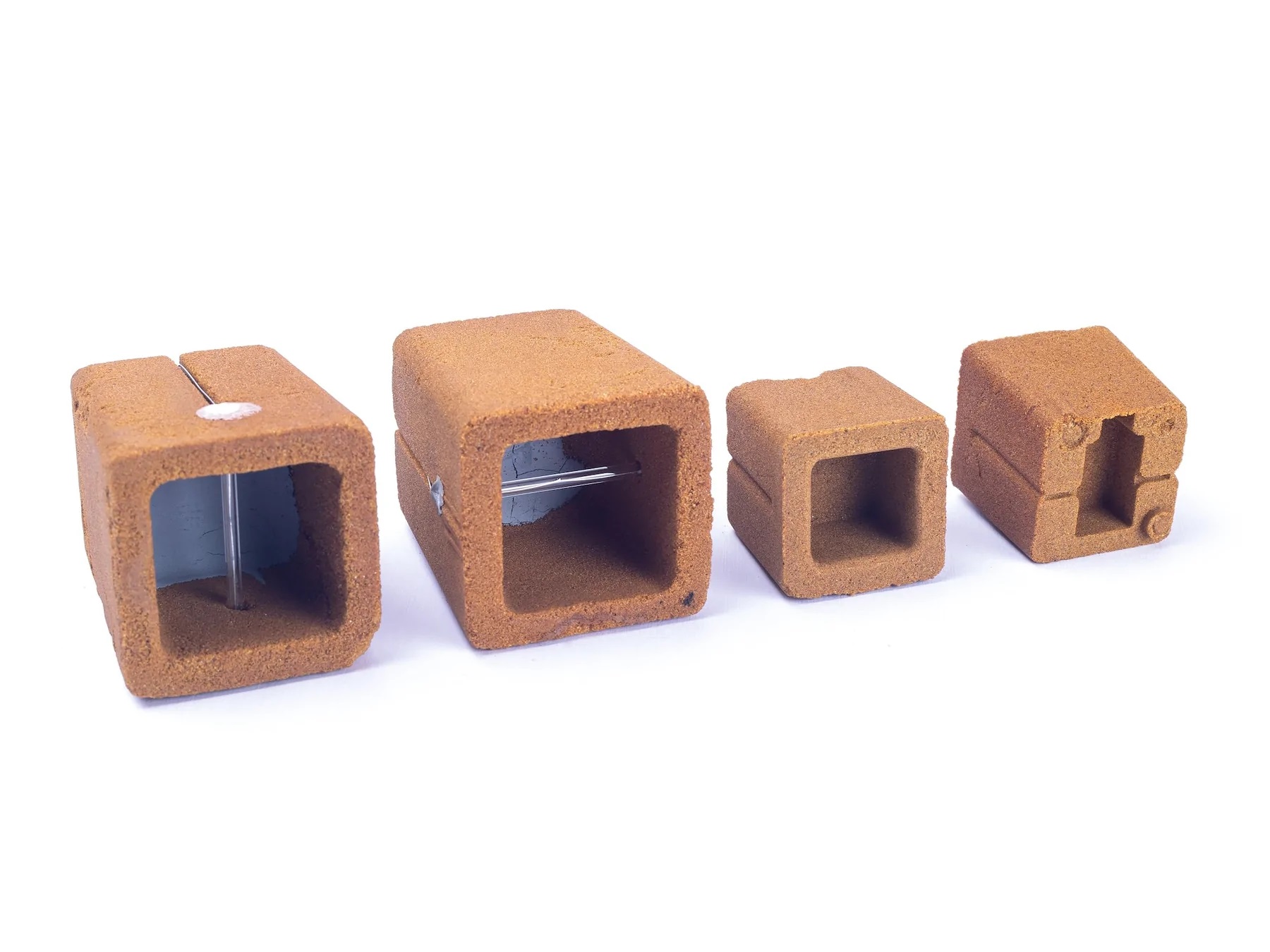

Immersion samplers are used for taking samples of molten metal. The sampling probes are designed with advance techniques for a safe, rapid and direct sampling and for reduction of total sampling and analysis time for producing clean steel. Sampler is mainly used to quickly take out a steel sample for spectrum analysis; it has structure, convenient application, widely used in electric furnance steel making, converter steel making, continuous casting and other process. Molten steel sampler, which are widely used in continuous casting and secondary steel making furnance converter refining process etc. According to whether the deoxidant is added in sampler. Immersion molten steel sampler can be classified as deoxidant kind and without deoxidant kind. We manufacture Immersion Samplers in the following shapes Round Samplers Oval Samplers Dual Thickness Samplers Stream Samplers Blast Furnace Samplers Immersion Samplers with varying paper tubes lengths upto 1800mm. We offer three shapes of samplers: Oval, Round and Double thick. By using stringent quality assurance procedures, our team of quality controllers ensures that the premium quality of the offered product is maintained at all times. Manufactured following the set industry norms and guidelines, utilizing high grade raw materials and advanced technology, the offered product is known to have a superior performance, capacity, strength and a longer functional life. In addition to this, the offered range is marked at a market leading rate. Features Oval : (33mm X 42mm) Round : (33mm X 33mm) Double thick : (33mm X 60mm) Features Samples can be obtained within 5 seconds Samples are easily detachable from the spoon De-oxidants as per customer requirements (Plain, Aluminium, Titanium, Zirconium) Minimal preparation required on the sample for analysis Zero defect samples Using method Sample taken from the metal bath must be Representative, Free of inclusions, cracks and holes Suitable, in shape and size. While taking the sample of molten metal the sampler should be sunk to the depth depending on the temperature and the viscosity of the melt at an angle of 55° for 3 to 5 second (the depth and time should be strictly carried out for its best performance). After taking the sample instrument from the furnace, knock the non immersed part on the ground, so the sample of steel will fall down on the ground. It is best to take a sample when the molten steel temperature is above 1500°C. Application It is used for process analysis of molten metal for instantaneous sampling techniques and reinforces quality control. This product is used for sampling directly from a stream or a ladle spoon. Advantage Cost Effective, quality built, precise, accurate & reliable to use